102 Australia

This slow burn renovation is part of an incremental path towards an intended EnerPHit certified Passive House renovation.

The original home is a typical Inner West Sydney single storey terrace with the usual mix of tack-ons out the back and tight internal spaces.

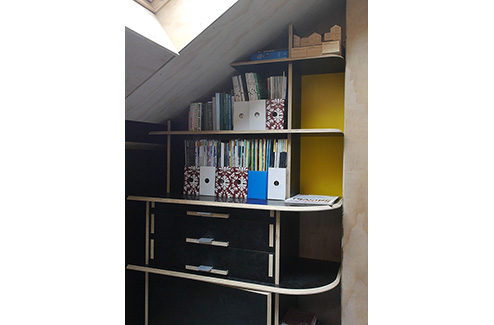

The first construction stage is the attic conversion to provide a home office with ladder access until Stage 2 can provide a more permanent staircase. The plywood lined space exudes calm and the sky views are the best outlook in the house.

Project Details

The attic has been heavily insulated for a total R value of ~R6 in the roof and R2.5 in the party walls. Two east facing high performance skylights have been added to provide natural light and ventilation. Low Solar Heat Gain Coefficients reduce summer overheating while the low U values keep the space toasty warm in winter.

Air tight membranes have been installed including taping around structural timbers. A time consuming and educational exercise in the steps necessary to achieve airtightness in a renovation project.

The home has been blower door tested several times. The first test achieved an air change rate of 15 ACH50 (air changes per hour at 50Pascals of pressure).

A series of small modifications were made including secondary glazing to all existing windows, caulking of wall ceiling joints, draught sealing measures at doors and sealing of flooring.

These changes reduced the ACH50 to 10, a 33% decrease in air leakage bringing it inline with a compliant new UK home, Australia currently has no minimum requirement for air tightness in homes.

The OffCut Side Project

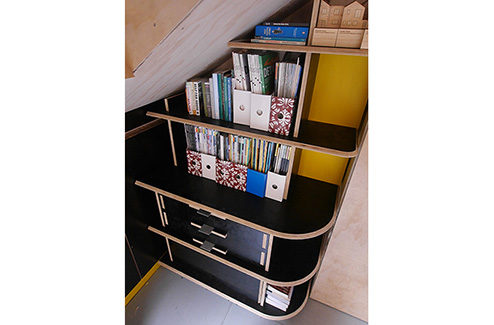

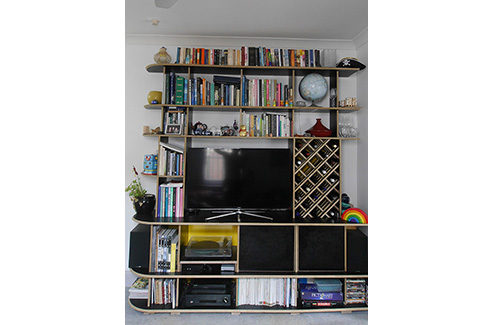

Various pieces of built in furniture have been designed and processed using a Computer Numerically Controlled (CNC) machine for the home. The accuracy of the design/production method is well suited to tight spaces where every millimetre matters.

The TV cabinet and office bookshelves arrived in sheet form and slot together each piece assembled in a matter of minutes. It shifts the time consuming part of the process from craftsman building to a design communicating to a machine.

The use of sheet materials resulted in some inevitable offcuts hence the OffCut Project.

Two tables are made from formply, LVLs and strips of leftover plywood. Square-drive decking screws hold it all together.

The hallway storage system is highly flexible with formply plates fixed to the walls, with plywood and LVL pieces used as shelves and hooks. The chamfered connection provides support and allows for easy rearrangement as desired.